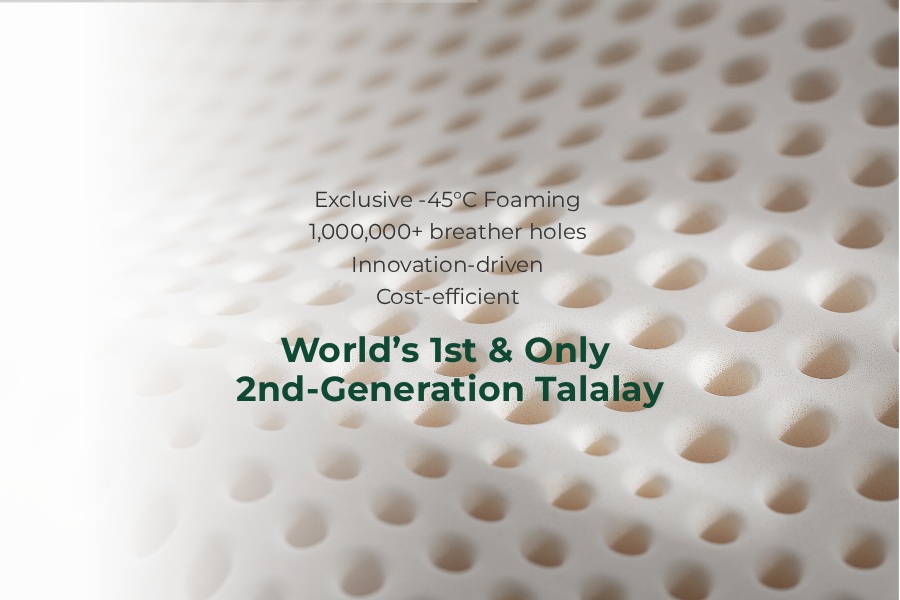

Updated Process

1.-45°C low-temperature shaping, physical foaming, “Cell-wall breaking” effect, unlocking molecules.

2.Improved process, effectively reducing energy consumption and providing cost advantages.

3.Automated production equipment, capable of mass production.

Toxic Substances Free

Uses "vacuum freezing + physical foaming" to replace chemical foaming agents, the process is more complex and environmentally friendly, safe and healthy

Elasticity & Toughness

1. Excellent elasticity, open-cell latex molecular structure, effectively maintains the natural curve of the head and neck, providing even support

2. High toughness, strong tensile strength, and not easily damaged

Breathability

Adopting ultra-cold foaming technology, with an open-cell rate of up to 99.9%, blasting 250,000+ micropores per pillow to create a full-domain honeycomb 3D ventilation network. The pillow breathes like it’s alive, staying so dry you’ll forget the word “sweaty” exists!

Temperature adjustability

Can “read” ambient temperature, keeping the pillow in perfect sync with the room at all times.

Anti-mite & Antibacterial

99.9% mite-proof, mites and bacteria can’t get close—or survive.

Languages

Languages Home

Home Products

Products Company

Company Contact Us

Contact Us